Email: info@esttoolsteel.com | Call Us: +91 22 2686 6600

Mould Steel

MOULD STEELS typically have lower carbon content—0.36 to

0.40% and chromium and nickel are the main alloying

elements. These characteristics allow these materials to be

polished to an extremely high finish.

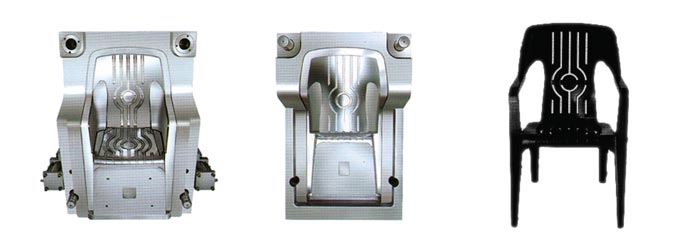

These steels are supplied in a variety of pre-hardened

conditions. They are primarily used for low temperature diecasting

dies and for molds to form plastics.

Characterised by the following properties, among other things:

- Wear resistance

- Polishability

- Machinability

- Toughness and hardness

- Thermal conductivity

STANDARD STOCK GRADES & COMPARABLE STANDARDS

| EST | GB | DIN | ASTM | JIS | OTHER |

| YTG136 | 4Cr13 | 1.2083  |

SUS420 | ||

| YTG173 | 3Cr17Mo | 1.2316  |

|||

| YTJ20A | 3Cr2Mo | 1.2311 | P20 | ||

| YTJ21 | 3Cr2NiMo | 1.2738 |

P20+Ni | ||

YTJ80  |

10Ni3MnCuAl |

STANDARD STOCK SIZES

| PRODUCT | DELIVERY CONDITION AND AVAILABLE DIMENSIONS | |||

| ROUND | CENTERLESS GROUND | PEELED | TURNED | |

| DIAMETER IN MM | 8.5 - 30.0 | 16 - 75 | 75 - 710 | |

| SQUARE | FORGED / ALL SIDE MILLED | |||

| SIZE IN MM | 55 X 55 - 610 X 610 | |||

| FLATS | HOT ROLLED BLACK | HOT ROLLED, 2 EDGE MILLED | FORGED ALL SIDE MILLED | |

| THICK x WIDTH IN MM | 6 - 30 X 20 - 130 | 13 - 100 X 150 - 410 | 100 - 505 X 100 - 1200 | |

OTHER GRADES AND SIZES ON REQUEST