Email: info@esttoolsteel.com | Call Us: +91 22 2686 6600

- You are here:

- Home

- Products

- High Speed Steel

- DF6M

DF6M

High Speed Steel With Strong Ductility

| Chemical Composition | C | Si | Mn | Cr | W | Mo | V | Co |

| (Typical analysis %) | 0.80 | 0.38 | 0.42 | 5.30 | 5.00 | 5.00 | 1.70 | 1.00 |

Property:

- On the basis of DF6(M2), EAST TOOL developed DF6M, a high speed steel with strong ductility, which improves the ability to resist tipping and rupture.

- DF6M controls the chemical composition, especially the carbon content and its carbide particle is even and fine. For this reason, DF6M has strong ductility and excellent thermoplasticity.

- Adding small amount of cobalt in DF6M improve the ability to resist to hot crackability when over loading.

- Through Electro Slag Remelting (ESR) the composition of DF6M is purified and improved to resist crack and tipping.

Application:

Be used for tools and dies to resist tipping and stand wear & tear better then M2

Steel density 8.16g/cm3

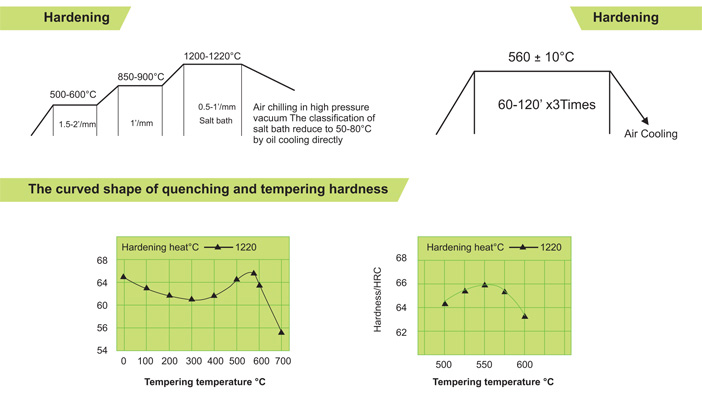

General Method of heat treatment

Azotization:

Temperature is 40°C lower than tempering temperature, and the specific temperature Is determined by mould design.

Relieving stress:

Steel temperature is 15-20°C lower than tempering temperature, keep the temperature for 2 hours and then air cooling.