Email: info@esttoolsteel.com | Call Us: +91 22 2686 6600

- You are here:

- Home

- Products

- High Speed Steel

- DF6Co

DF6Co

Cobaltic And Abrasion Resistant High Speed Steel

| Chemical Composition | C | Si | Mn | Cr | W | Mo | V | Co |

| (Typical analysis %) | 0.90 | 0.38 | 0.35 | 4.10 | 6.00 | 4.80 | 1.80 | 1.40 |

Property:

- Basing on DF6 (M2), EAST TOOL introduced cobaltic high speed steel DF6Co, which has stronger wearlessness, better red hardness, and keep high tenacity.

- Moderate saturation degree of carbon (keep between M2 and high carbon M2C), improve the workable hardness of DF6Co, and keep the high tenacity of M2 steel.

- After adding in a right amount of cobalt, DF6Co gets better red hardness. Adding cobalt contributes to stability of carbide and maintenance of fine grain in work, improves the tempering stability of steel and keeps in state of strong wearlessness.

Application:

End mill, Slitting saws, extra hard lathe bit, machine tap, circular saw blades, etc. When processing stainless steel and titanium alloy, DF6Co has better efficiency than M2

| Cutting tool | End mill, side and face cutter |

Slitting saws blade | Extra hard lathe bit | Screw Tap | H.S.S. Circular Saw Blade |

| Workable hardness | 65-66 | 64-66 | 65-67 | 64-66 | 64-66 |

Steel density 8.16g/cm3

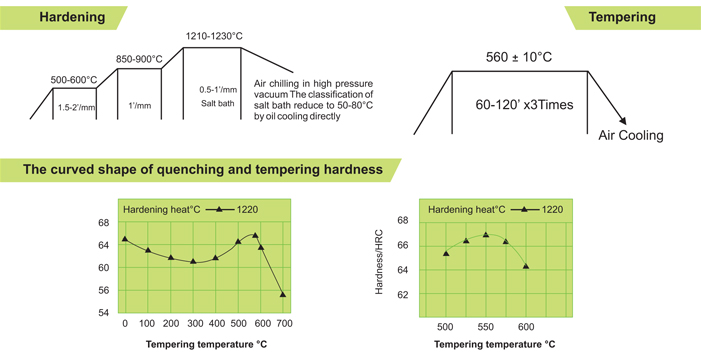

General Method of heat treatment

Azotization:

Temperature is 40 lower than tempering temperature, and the specific temperature Is determined by mould design.

Relieving stress:

Steel temperature is 15-20°C lower than tempering temperature, keep the temperature for 2 hours and then air cooling.